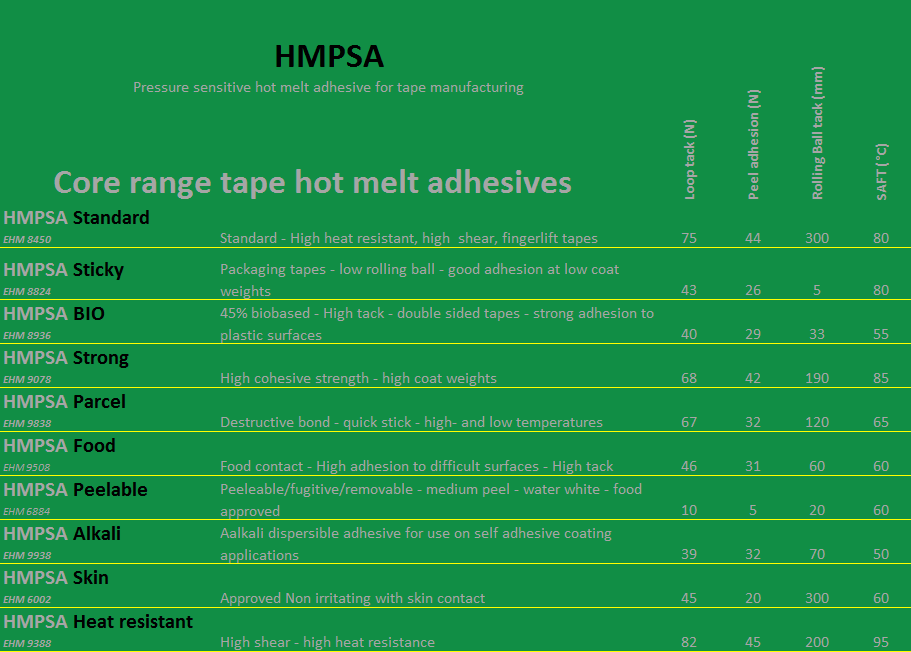

SIS hot melts are part of or PSA hot melt range, depending on your application requirements we can advice one of our products and can produce manual samples in our hot melt adhesive laboratory.

PSA hot melt adhesives

Pressure sensitive hot melt adhesives are used is a wide array of applications. Pressure-sensitive hotmetls hold two substrates together by little contact. External pressure is needed to bond two substrates, that’s why these adhesives are knows as Pressure sensitive. There are hundreds of grades of PSA hotmelts which can offer a permanently tacky aggressive bond ot removable fugitive glues which offer a temporary bond. PSAs can be bond numerous materials like paper, plastic, metal, glass, wood, etc.

Product assembly PSA hotmelts

Pressure sensitive adhesives are often used for assembly purposes. All hotmelt applications, including PSA, can be easily automated, just putting a sensor on a production line and a nozzle which opens when your products goes along. PSA hot melts save time in production compared to solvent- or waterbased- adhesives as they require no setup or long curing time, a quick cool down to room temperature is all that’s needed.

Bulk hot melt manufacturing

Using bulk pressure sensitive hot melt adhesives provides many advantages. No need for rives, screws, clips, or drilling holes which harm the structure and coating of your products. Pressure sensitive adhesives eliminate the need, are quickly and low cost applied. More advantages can be the insulating seal properties as well as sound deadening and vibration cancellation.