At Intercol we serve several applications in the winding industry with our adhesives. Both waterbased, and hot melt adhesives. For special applications even watersolluble hot melt adhesives.

Winder: Core Gluing Device, Function

Function of glue nozzle

Glue is sprinkled in the middle of a nozzle

High pressure air jets is caused a spiral

figure for a glue strip.

Winder: End Gluing

• The purpose of end gluing is to attach the end of the web section to the shipping roll

• The end gluing device is located under the center drum

• Glue is applied on the webs in stripes of desired length as the winder is decelerating

for set change. Once the glued web has proceeded into the nip between the roll and

winding drum, the topmost web in the roll and the glued web are glued together.

• In set change the web is cut off and the glued web remains in the roll

Winder: End Gluing -Glue Tank and Glue Pump

• The end gluing device includes a glue container, a glue pump, washing water container

and filters for the glue and washing water.

Winder: End Gluing – Attaching glue to the web

2 3 4

1 Glue nozzle box and cover (1a)

2 Glue nozzle

3 Guide bar

4 Openings of the guide bar

5 Pneumatic lifting cylinders

Wrapping principle

Wrapping material: laminated kraft/ testliner

Protective thick inner heads

Hot melt gluing

Laminated sealable outer heads

Markings and labels

Feeding Table and Gluing

Nordson Hot-Melt gluing device: The

gluing device includes the main unit for

the melting of glue, heated glue hoses

and line of gluing guns with nozzles at

each 50 mm across the feed table.

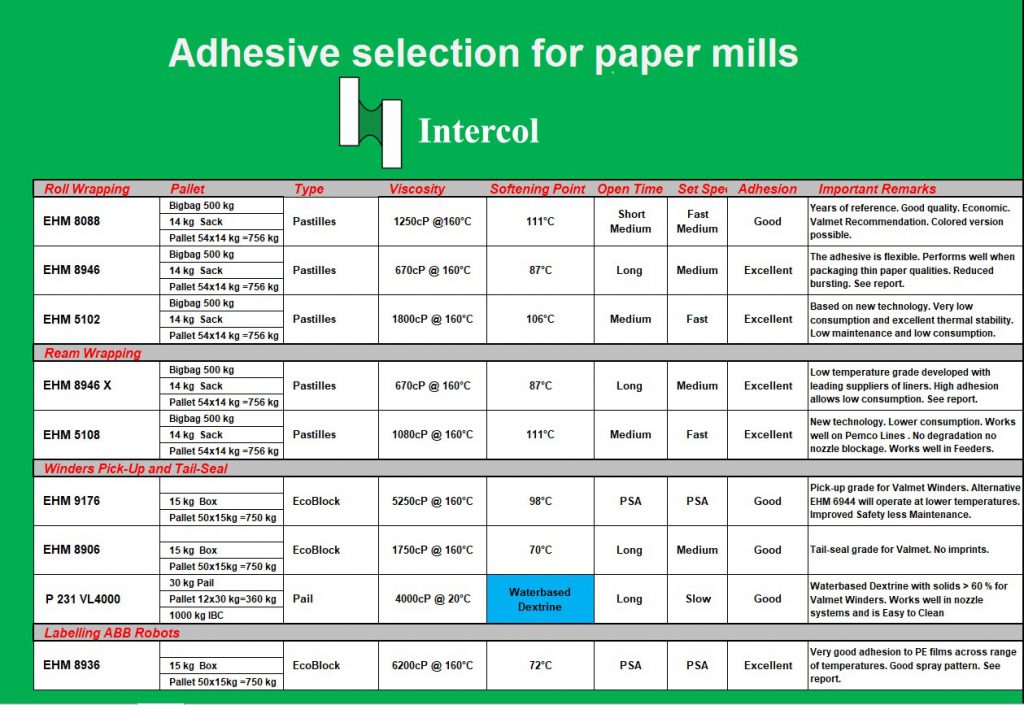

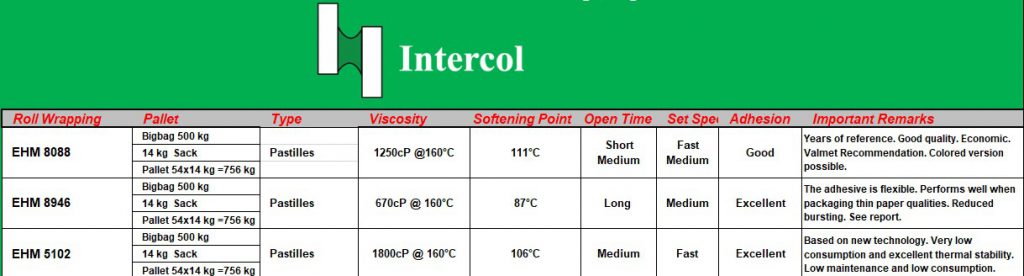

Roll wrapping

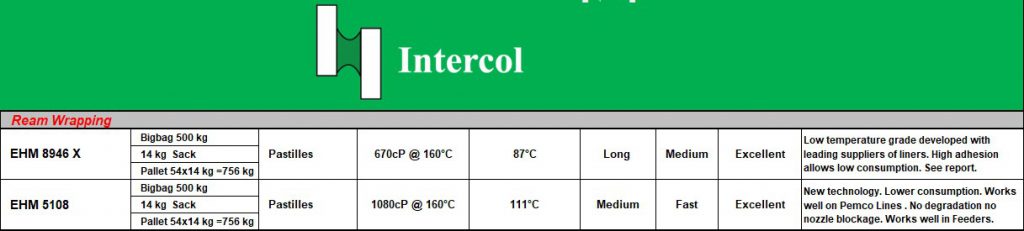

Ream Wrapping

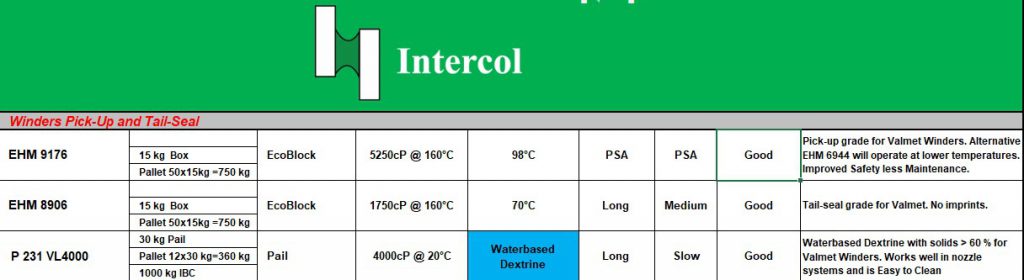

Winders Pick-up and tail-seal

Labelling on ABB robots

| Roll Wrapping | Pallet | Type | Viscosity | Softening Point | Open Time | Set Speed | Adhesion | Important Remarks | |

| EHM 8088 | Bigbag 500 kg | 1250cP @160°C | 111°C | Short Medium | Fast Medium | Good | Years of reference. Good quality. Economic. Valmet Recommendation. Colored version possible. | ||

| 14 kg Sack | Pastilles | ||||||||

| Pallet 54×14 kg =756 kg | |||||||||

| EHM 8946 | Bigbag 500 kg | Pastilles | 670cP @ 160°C | 87°C | Long | Medium | Excellent | The adhesive is flexible. Performs well when packaging thin paper qualities. Reduced bursting. See report. | |

| 14 kg Sack | |||||||||

| Pallet 54×14 kg =756 kg | |||||||||

| EHM 5102 | Bigbag 500 kg | Pastilles | 1800cP @ 160°C | 106°C | Medium | Fast | Excellent | Based on new technology. Very low consumption and excellent thermal stability. Low maintenance and low consumption. | |

| 14 kg Sack | |||||||||

| Pallet 54×14 kg =756 kg | |||||||||

| Ream Wrapping | |||||||||

| EHM 8946 X | Bigbag 500 kg | Pastilles | 670cP @ 160°C | 87°C | Long | Medium | Excellent | Low temperature grade developed with leading suppliers of liners. High adhesion allows low consumption. See report. | |

| 14 kg Sack | |||||||||

| Pallet 54×14 kg =756 kg | |||||||||

| EHM 5108 | Bigbag 500 kg | Pastilles | 1080cP @ 160°C | 111°C | Medium | Fast | Excellent | New technology. Lower consumption. Works well on Pemco Lines . No degradation no nozzle blockage. Works well in Feeders. | |

| 14 kg Sack | |||||||||

| Pallet 54×14 kg =756 kg | |||||||||

| Winders Pick-Up and Tail-Seal | |||||||||

| EHM 9176 | EcoBlock | 5250cP @ 160°C | 98°C | PSA | PSA | Good | Pick-up grade for Valmet Winders. Alternative EHM 6944 will operate at lower temperatures. Improved Safety less Maintenance. | ||

| 15 kg Box | |||||||||

| Pallet 50x15kg =750 kg | |||||||||

| EHM 8906 | EcoBlock | 1750cP @ 160°C | 70°C | Long | Medium | Good | Tail-seal grade for Valmet. No imprints. | ||

| 15 kg Box | |||||||||

| Pallet 50x15kg =750 kg | |||||||||

| P 231 VL4000 | 30 kg Pail | Pail | 4000cP @ 20°C | Waterbased Dextrine | Long | Slow | Good | Waterbased Dextrine with solids > 60 % for Valmet Winders. Works well in nozzle systems and is Easy to Clean | |

| Pallet 12×30 kg=360 kg | |||||||||

| 1000 kg IBC | |||||||||

| Labelling ABB Robots | |||||||||

| EHM 8936 | EcoBlock | 6200cP @ 160°C | 72°C | PSA | PSA | Excellent | Very good adhesion to PE films across range of temperatures. Good spray pattern. See report. | ||

| 15 kg Box | |||||||||

| Pallet 50x15kg =750 kg | |||||||||